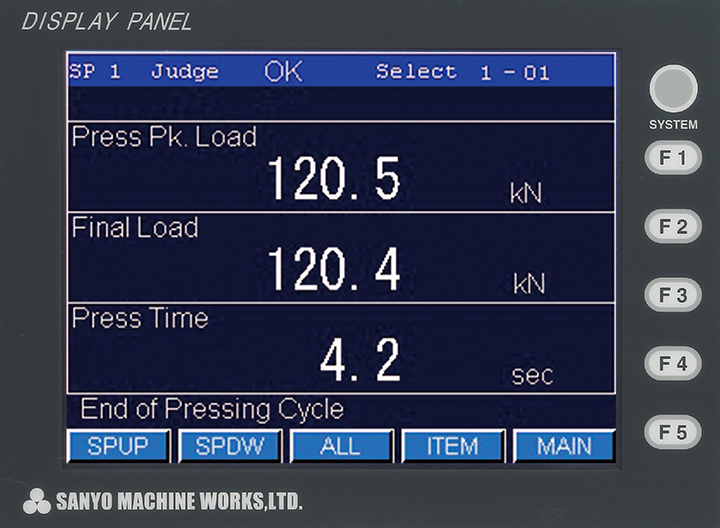

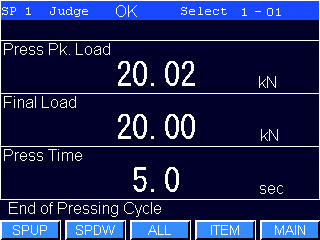

● High Performance

The clamping force is confirmed and validated by pressure sensors to ensure the quality and precision of the clamping. The precision can reach ±2% (3σ/max load), exhibiting outstanding performance and high repeatability, making this tool an ideal choice for managing insertion depth.

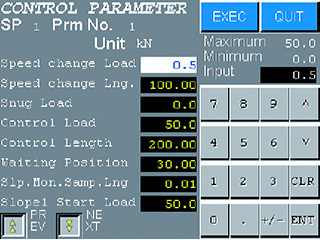

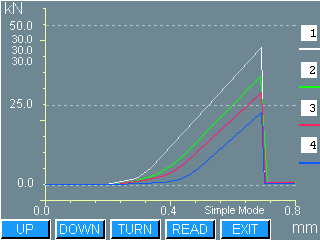

● High Precision Software Servo Control

The proven servo control technology combined with a high-speed CPU enables high-precision pressure control for precise adjustment of pressure and pressing distance.

To ensure outstanding durability, the SANYO servo press has passed rigorous 1 million cycle tests under rated load. Through our traceable inspection and management system, all equipment undergoes functional and pressure accuracy testing before shipment.

● Flexible Clamping Program Settings

Eight different clamping programs and 32 independent clamping parameters can be pre-programmed for each connected clamping tool.

This flexibility allows operators to implement clamping processes using methods such as load method, distance method, or a combination of both.

Various clamping options are also available, such as load holding.

● Interface Options

The main controller has multiple optional card interfaces, such as I/O cards and fieldbus cards, to support various manufacturing systems and field networks.

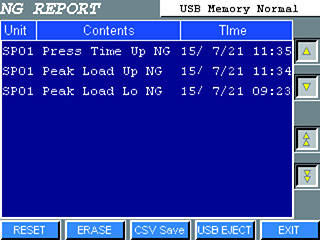

● Powerful Judgment Function

Based on monitoring of over 45 clamping data and more than 60 clamping errors, the SANYO servo press can achieve high-quality clamping every time.