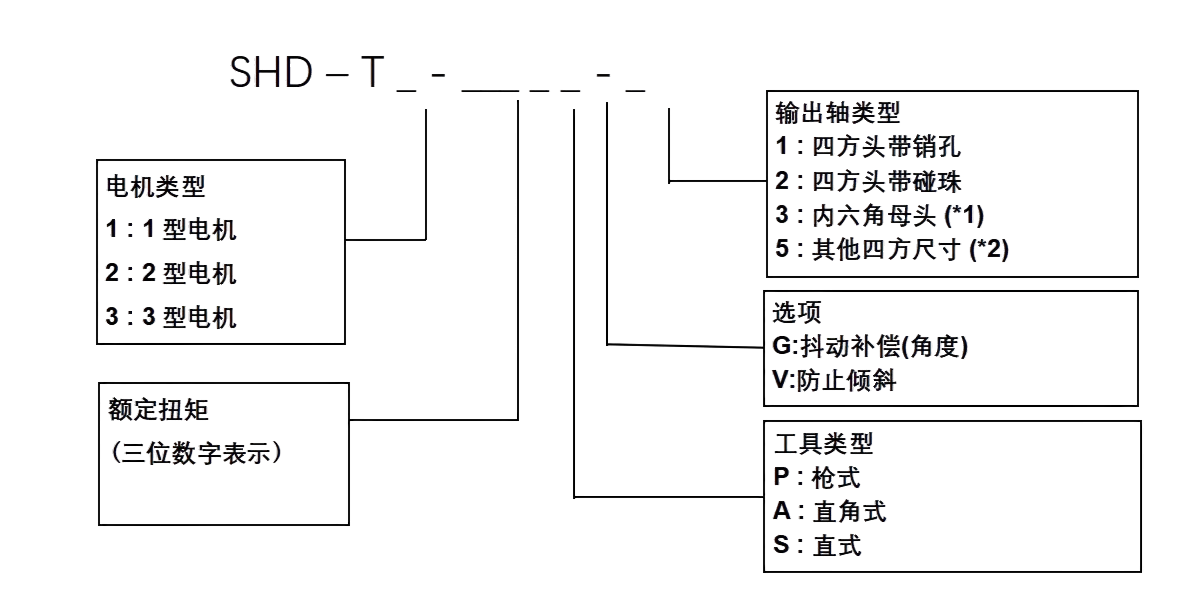

High precision tightening, high durability, and excellent reliability

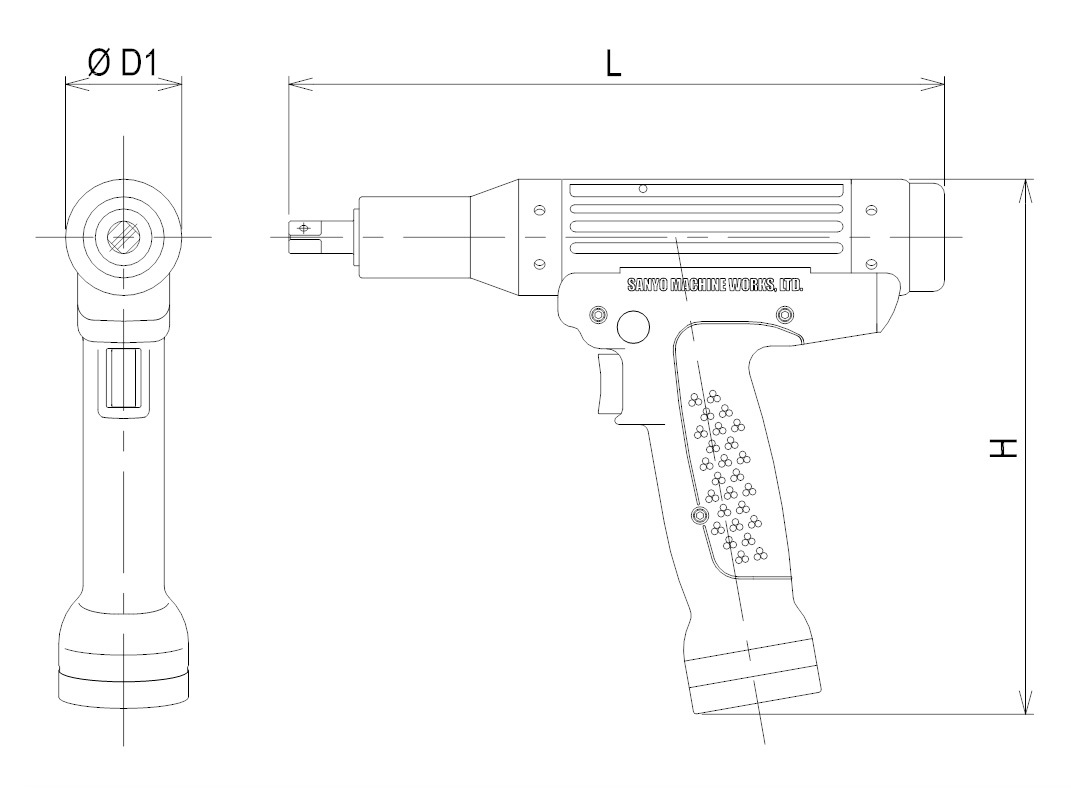

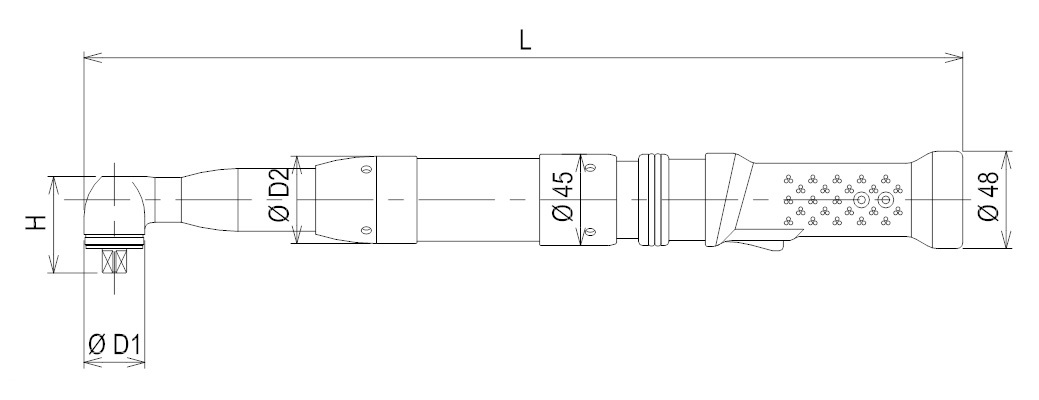

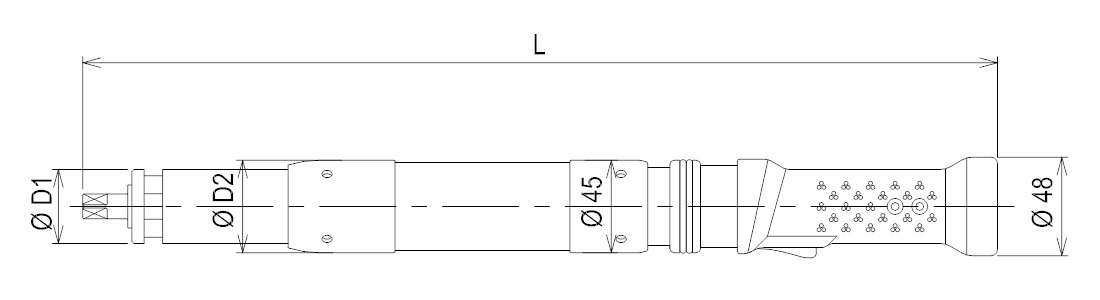

The newly designed high-speed gun-type tool (SHD-T2 series) can achieve a free speed of more than three times that of the previous generation products. At the same time, the braking performance of the motor has been improved, allowing the tool to stop quickly after reaching the seating torque even at high speeds, reducing the tightening cycle time.

Through continuous operation tests at a rated torque of 1 million times to ensure the high durability of the tool, while the high precision and high efficiency planetary reducer allows our tools to maintain low noise characteristics while ensuring durability.

Multiple tightening modes

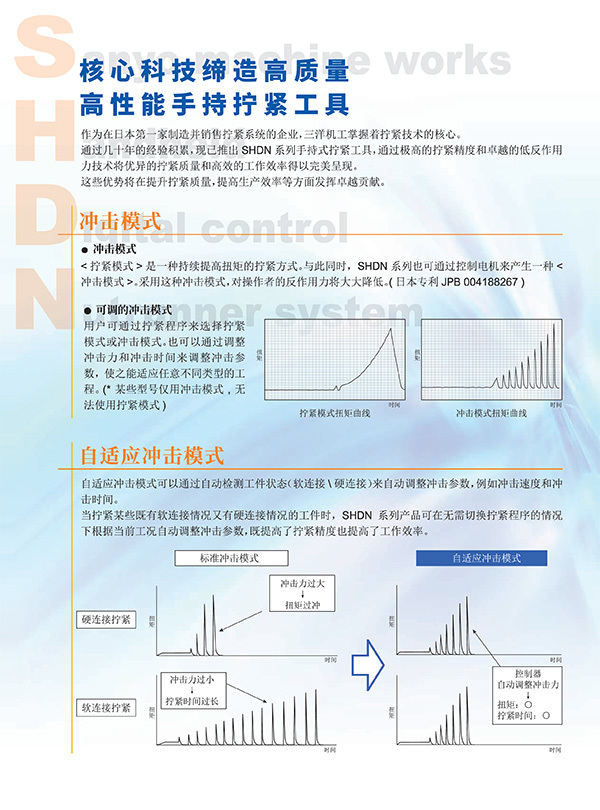

● Impact mode

is a tightening method that continuously increases torque. At the same time, the SHDN series can also generate an by controlling the motor. Using this impact mode will greatly reduce the reaction force on the operator.Japanese Patent JPB 4188267)

● Adjustable impact mode

Users can select the tightening mode or impact mode through the tightening program. They can also adjust the impact parameters by changing the impact force and impact time to adapt to various types of projects. (*Some models are for impact mode only and cannot use tightening mode)

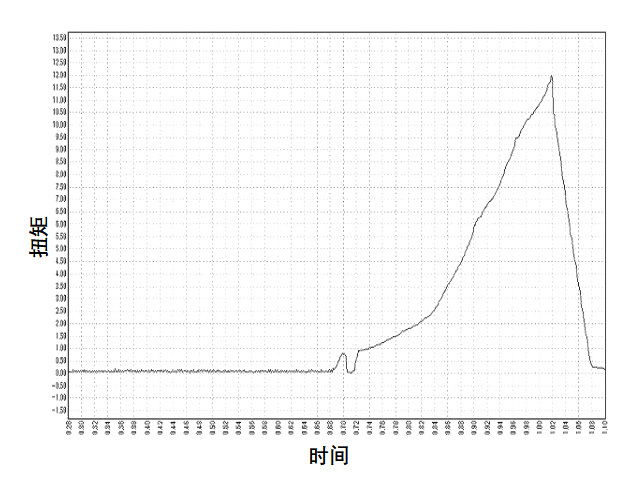

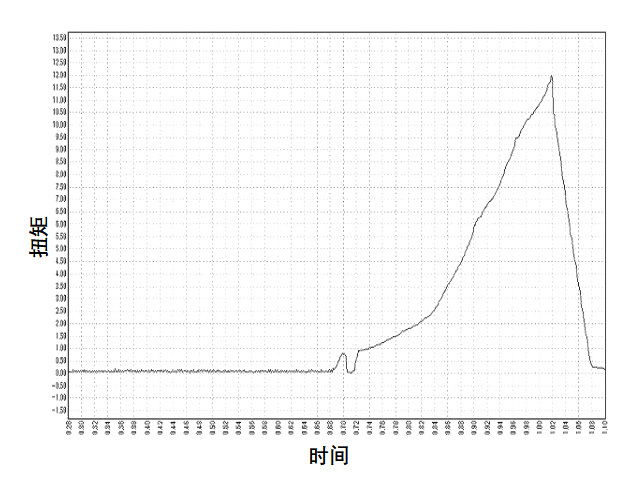

Tightening mode torque curve

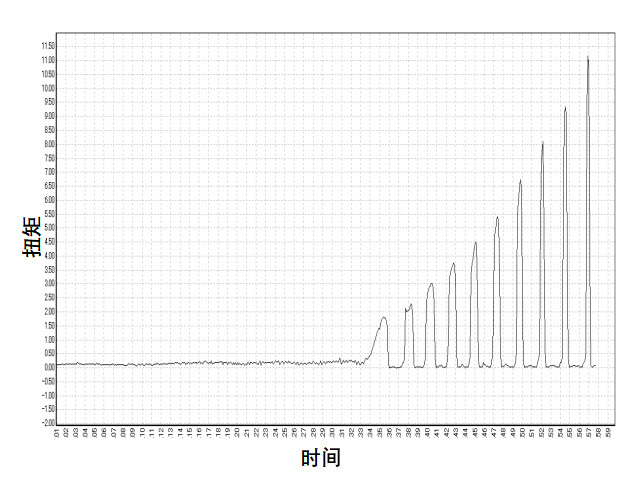

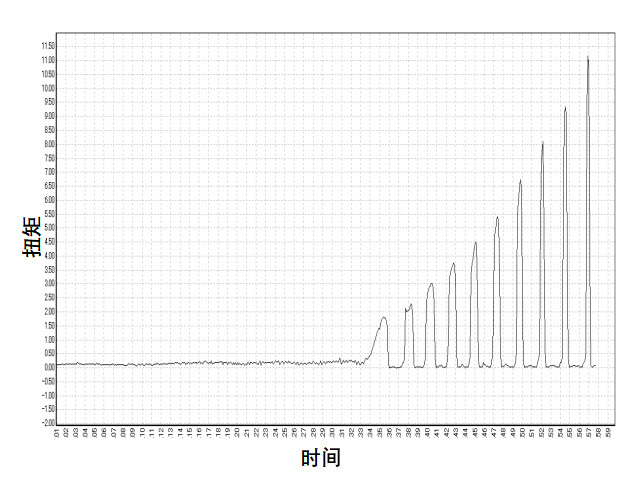

Impact mode torque curve

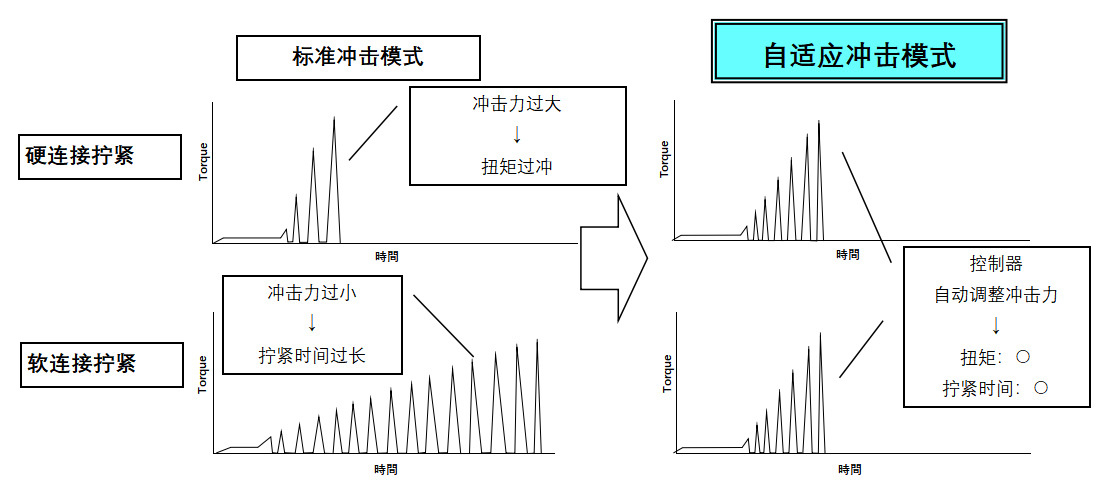

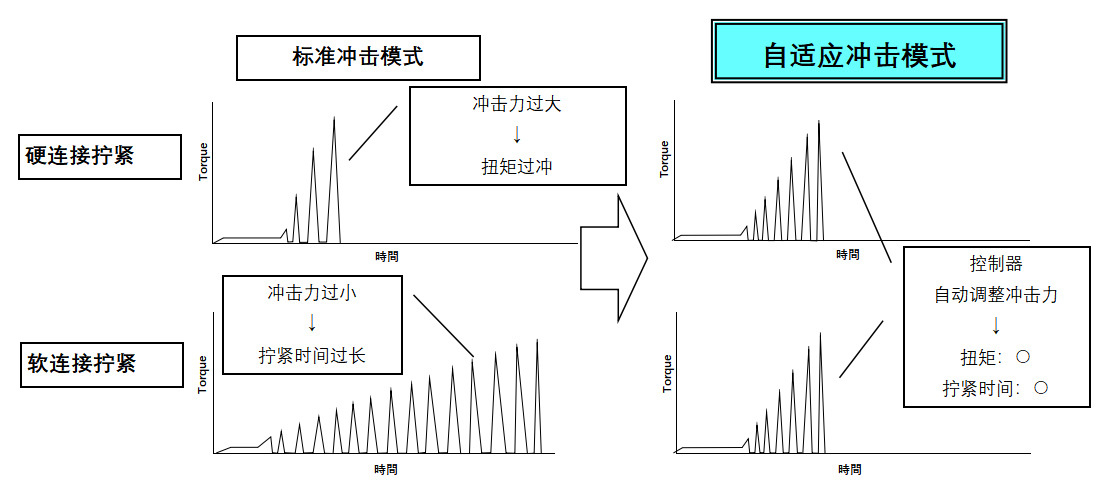

● Adaptive impact mode

The adaptive impact mode can automatically adjust the impact parameters, such as impact speed and impact time, by automatically detecting the workpiece status (soft connection/hard connection).

When tightening workpieces that have both soft and hard connections, the SHDN series products can automatically adjust the impact parameters according to the current working conditions without switching the tightening program, improving both tightening accuracy and work efficiency.

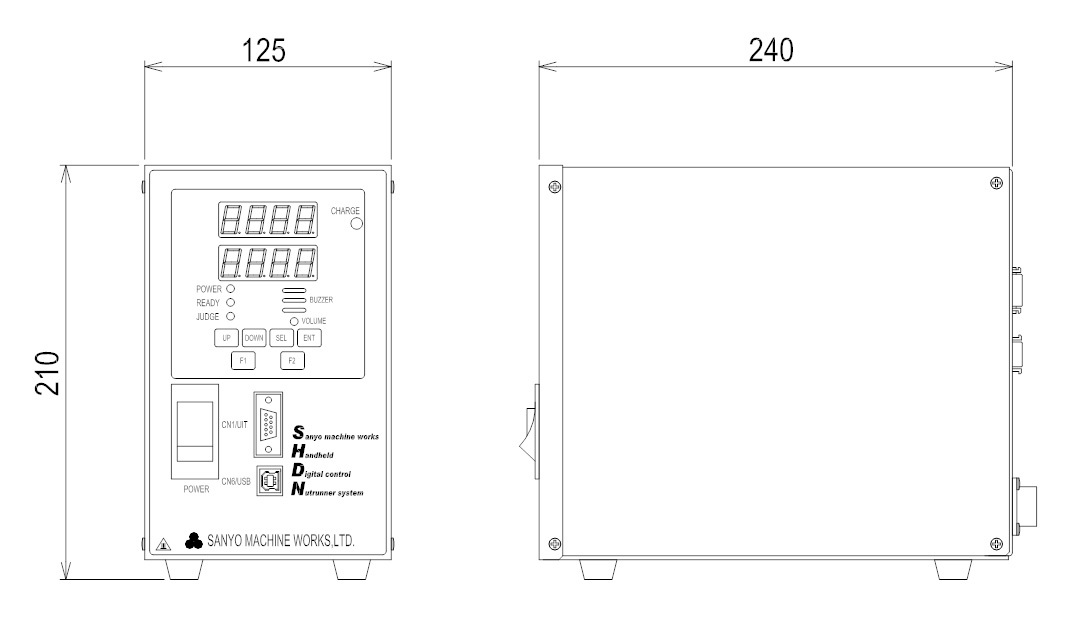

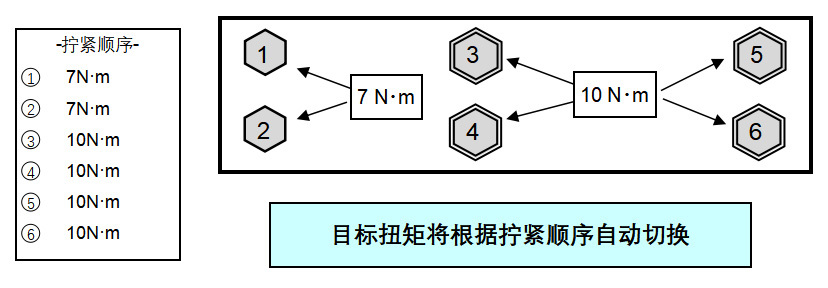

Batch counting function

● Tightening count

The batch counting function can record the number of tightenings and output an OK signal after reaching the set value. This can prevent errors such as missed tightening or double tightening that may occur when a workpiece is tightened multiple times.

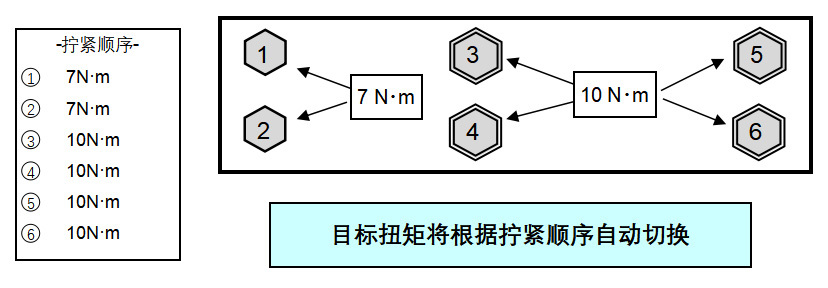

● Automatic switching of tightening programs

If the tightening processes are different during multiple tightenings on a workpiece, the counting function can automatically switch between different programs during the batch counting process based on the relevant settings.

● Rich counting setting options

The SHDN series has various counting setting functions, such as counting increase/decrease status indication, tightening OK count, tightening OK + NG count, and counting increase/decrease settings after loosening; these settings make the tool suitable for various complex tightening processes.

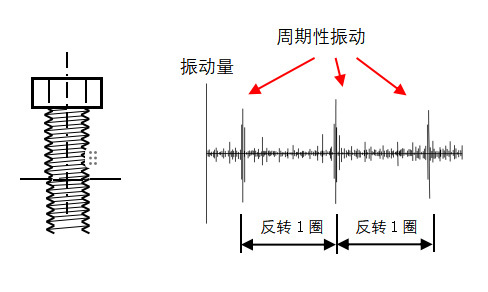

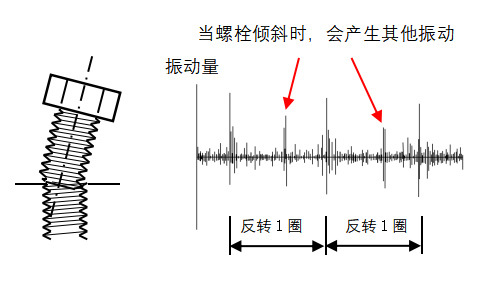

Preventing inclined insertion technology

After aligning the threaded hole, detect the meshing state between the bolt and the threaded hole.

First, reverse the tool. When the end of the bolt thread interlaces with the starting point of the threaded hole, vibration will occur. The amount of vibration generated when the bolt is perpendicular to the threaded hole is different from when the bolt is not perpendicular to the threaded hole. By detecting the magnitude of the vibration, the posture of the bolt can be determined.

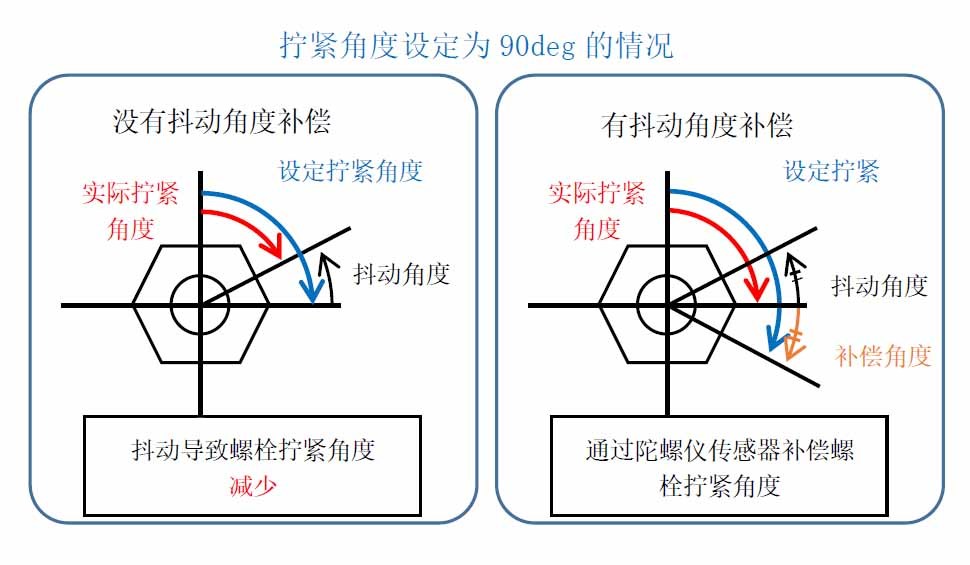

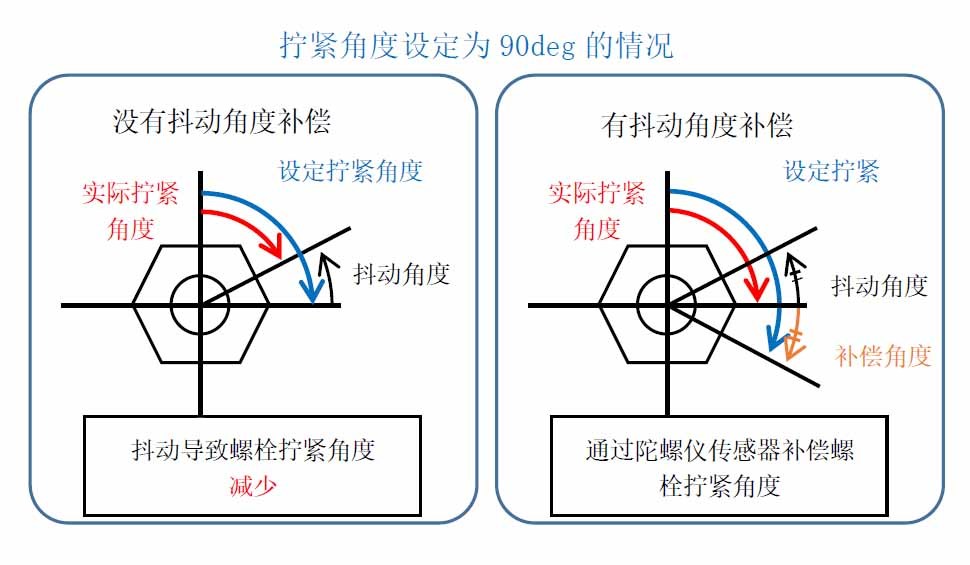

Vibration angle detection and compensation

The tool is equipped with a gyroscope sensor, which measures the tightening angle in real-time and corrects the vibration angle of the tool during the tightening process, allowing for tightening at the correct angle.

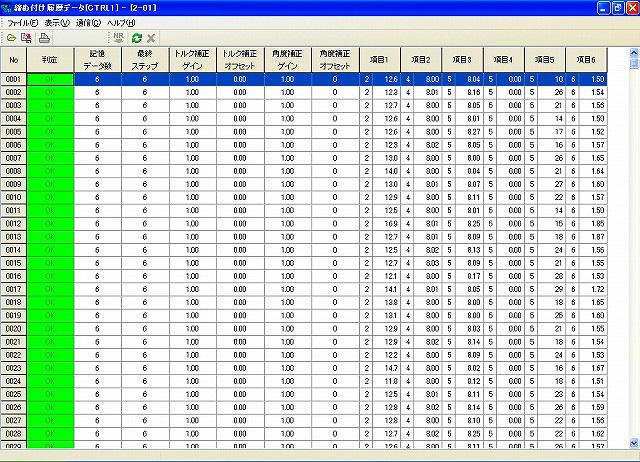

Rich tightening judgment functions

The SHDN series has rich tightening result judgment functions. It can make composite judgments on the tightening process based on different workpiece states to achieve high-quality tightening and can also detect the quality of the threads.

The SHDN series has up to 66 parameters for judging the tightening process and results, including 32 NG parameters and 34 TROUBLE parameters.