Application of Handheld Tightening Tool G/V Function

Advantages of SANYO Handheld Tightening Tools

SANYO handheld tightening tools ensure a high qualification rate for bolt tightening while being easy for operators to use, thanks to their extremely high tightening precision and excellent low reaction force technology. The outstanding tightening quality and high work efficiency are perfectly presented. SANYO also offers V series tools with anti-tilt insertion features and G series tools with vibration angle detection compensation functions, which will make exceptional contributions to improving tightening quality and enhancing production efficiency.

Anti-Tilt Insertion Technology

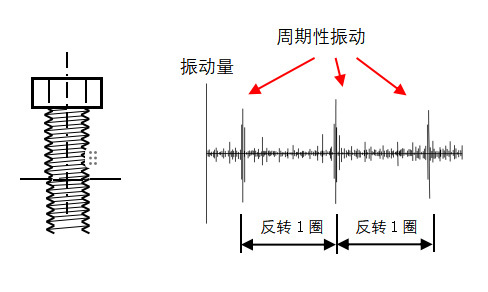

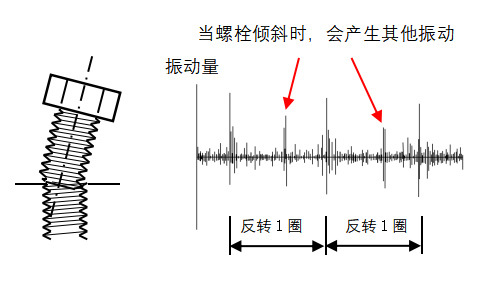

The V-type tool has an anti-tilt insertion function. After the bolt is aligned with the threaded hole, it detects the engagement state between the bolt and the threaded hole. The tool first reverses, and when the end of the bolt thread interlaces with the starting point of the threaded hole, vibration occurs. The amount of vibration generated when the bolt is perpendicular to the threaded hole differs from that when it is not. When the tool detects tilt, a purple indicator light flashes, and the bolt cannot be inserted in reverse; when the bolt is no longer tilted, it can be inserted in the forward direction. By measuring the magnitude of the vibration, the posture of the bolt is determined, preventing damage to the bolt and threaded hole, and improving the qualification rate of bolt tightening.

Anti-Tilt Insertion Technology

Anti-Tilt Insertion Demonstration (AGV Type)

Anti-Tilt Insertion Demonstration (PV Type)

Vibration Angle Detection and Compensation

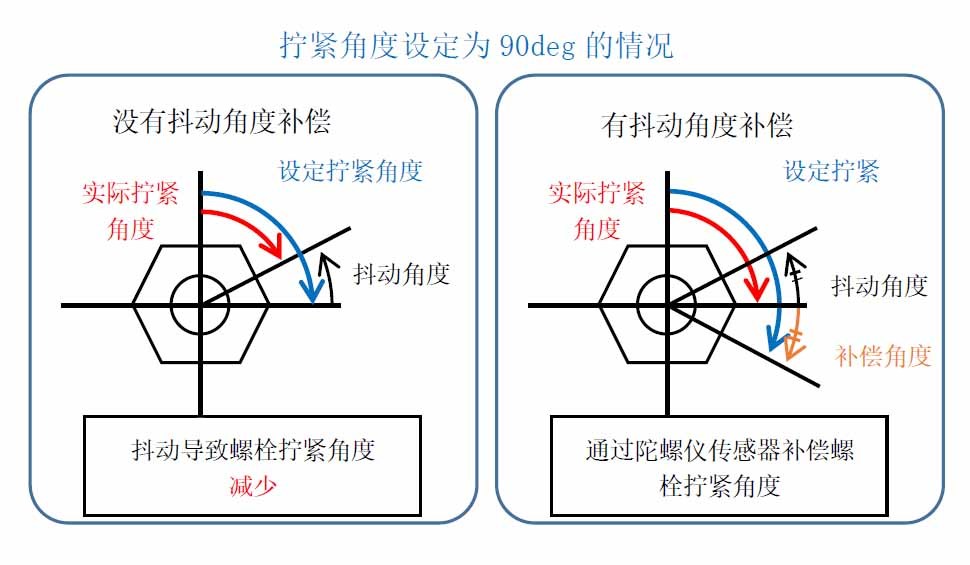

Vibration during the tightening process can cause the tightening angle to deviate from the set value. The G-type tool is equipped with a gyroscope sensor that measures the tightening angle in real-time and corrects the tool's vibration angle during the tightening process, allowing for tightening at the correct angle and improving the qualification rate of bolt tightening.

Vibration Angle Compensation Technology

When the vibration angle compensation function is not used, vibrations caused by misoperation and other factors can lead to the tightening angle being too large or too small. For example, if the tightening angle is set to 12°, vibrations during the tightening process can result in both tightening attempts failing to reach the set angle, with significant deviations.

Without Using Vibration Angle Compensation Function

When using the vibration angle compensation function, vibrations caused by misoperation and other factors are detected and corrected, resulting in the tightening angle being the same as the set value.

Using Vibration Angle Compensation Function

Previous Page:

Next page:

recommend News

Hydraulic System Design and Manufacturing Expert: Creating a Stable and Efficient Power System